What is the Cold Chain? 90% of Readers Still Misunderstand It

The cold chain plays a key role in preserving and transporting temperature-sensitive goods such as food and pharmaceuticals. Efficient cold chain management helps businesses optimize costs, improve product quality, and expand their markets. So what exactly is the cold chain? Let Tân Thanh Container walk you through all the details in the article below!

What is the Cold Chain? What is Cold Chain Logistics?

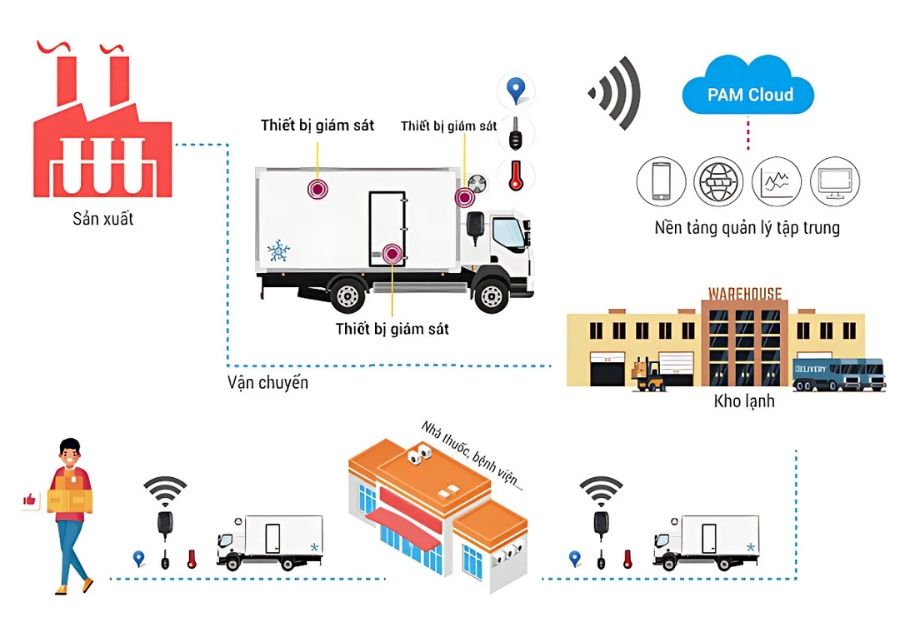

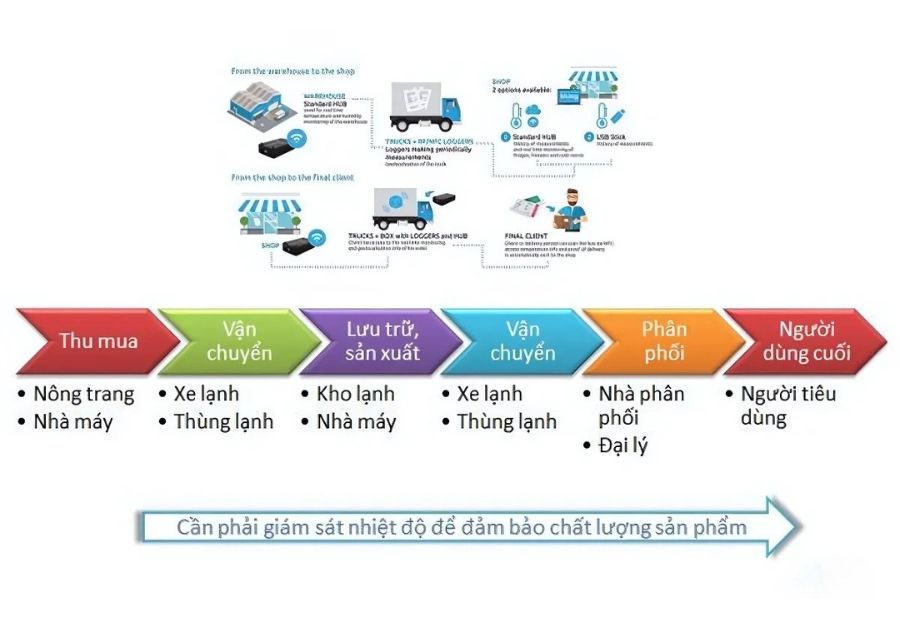

The cold chain (Cold Chain Logistics) is a temperature- and humidity-controlled system throughout the transportation and storage process of specific goods to ensure product quality before reaching the end consumer. These goods typically include food, seafood, frozen items, agricultural produce, pharmaceuticals, etc. In contrast, a regular supply chain is applied to goods that do not require special temperature or humidity conditions.

Basic Structure of a Cold Chain

The structure of a cold chain consists of two main elements:

Physical Infrastructure

In terms of hardware, the cold chain includes the following key components:

Temperature-controlled transport vehicles:

Refrigerated trucks: Road vehicles with insulated compartments equipped with refrigeration systems to maintain stable temperatures for domestic transportation.

Reefer containers: Containers integrated with refrigeration units, widely used in sea, rail, and cross-border land transport.

Refrigerated cargo ships: Specialized vessels designed to carry large volumes of frozen goods on long sea routes.

Cold-chain aircraft: Used for high-value, time-sensitive goods that require strict temperature control.

Temperature-controlled storage systems:

Cold storage warehouses: Large-scale facilities capable of long-term temperature control, used for storing various goods.

Cool storage: Maintains an environment between 0°C and 10°C, ideal for vegetables, dairy, and fresh fruits.

Freezer storage: Maintains temperatures below -18°C, suitable for storing meat, fish, seafood, and frozen products.

Cold distribution centers: Hubs where goods are gathered, processed, and sorted before being dispatched to retail outlets.

Operational Structure

On the organizational side, the cold chain is built upon coordinated processes among involved parties, including:

Quality management: Ensures goods meet hygiene, safety, and freshness standards.

Cold storage and transport operations: Manages daily warehouse and transport activities, ensuring optimal temperature conditions.

Traceability management: Tracks product routes, storage history, and transportation data.

Risk management: Implements protocols to handle equipment failures, temperature issues, or transportation incidents.

Producers and suppliers: Responsible for preprocessing, packaging, and pre-cooling immediately after harvest or production.

Transport providers: Ensure transportation via specialized vehicles that maintain stable temperatures.

Storage facilities: Preserve goods under controlled conditions before distribution.

Distributors/Agents: Act as intermediaries delivering goods to retail channels or consumption points.

Retailers: Deliver final products directly to consumers.

Quality control units: Inspect and ensure compliance with safety standards.

Supply chain coordinators: Oversee the entire process from storage to transportation and distribution.

Regulatory authorities: Issue, monitor, and inspect compliance with food safety and cold logistics regulations.

Importance of Cold Chain Management for Businesses

Effective cold chain management is vital for maintaining product integrity, minimizing risk, and optimizing operations. Specifically:

Extends shelf life and reduces spoilage rates: Cold chains can extend product lifespan 2–3 times longer and reduce spoilage by 60–70%, resulting in significant economic benefits.

Enhances customer experience: Better quality products satisfy customers, foster loyalty, and ensure steady revenue.

Expands international cooperation opportunities: International-standard cold chains facilitate exports, unlock global markets, and drive economic growth.

The Current State of Cold Chain Logistics in Vietnam

The cold chain is crucial in preserving freshness, quality, and safety for perishable goods like meat, seafood, vegetables, and dairy products. In Vietnam, demand for cold chain development is increasing due to changing consumer habits, booming e-commerce, and stricter export requirements. However, current infrastructure still faces limitations, especially with uneven distribution of cold storage—mainly concentrated in the southern region.

According to Vietnam Briefing, Vietnam’s cold logistics market is expected to reach approximately USD 295 million by 2025, driven by rising demand for fresh and frozen goods. Nonetheless, the sector still faces challenges such as high electricity costs, market fragmentation, and overcapacity in certain key areas.

Currently, some prominent players in this field include Lineage Logistics (USA), ABA Cooltrans, and Transimex (Vietnam), with cold storage facilities spread across Ho Chi Minh City, Hanoi, Binh Duong, and Bac Ninh. Despite the challenges, the industry still holds great potential thanks to free trade agreements (FTAs), advanced technologies such as IoT and blockchain, and increasing export demand.

The cold chain plays a vital role in ensuring the quality and safety of temperature-sensitive products. Investing in and developing an efficient cold chain system is crucial for businesses to enhance their competitiveness and meet the growing market demand.

In the cold chain, choosing high-quality refrigerated containers is critical to ensure operational efficiency and goods safety. With over 30 years of experience, Tân Thanh Container is a leading provider offering a wide range of refrigerated containers tailored to various customer needs. Tân Thanh Container is committed to delivering internationally standardized products at competitive prices, with a warranty policy of up to 2 years—helping businesses optimize costs and operate with peace of mind.

Phone: 0968 039 939

Email: info@tanthanhcontainer.com

Website: https://tanthanhcontainer.com/