Art School Built Using Shipping Containers

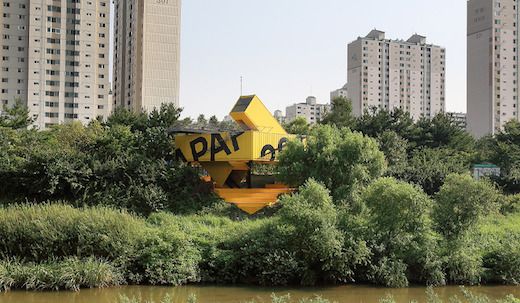

One of the benefits of using shipping containers as architectural building blocks is the ease with which they can be shaped into any kind of building, even one with a completely unique design. The architecture firm LOT:EK took that to the limit when designing and constructing the APAP OpenSchool in Anyang, Korea.

They used eight recycled shipping containers to construct this art school, which yielded a structure with 2,600 square feet of indoor space. The shipping containers were cut at a 45 degree angle and placed together in a fishbone pattern, which resulted in a building that is arrow-like and lifted three meters off the ground. One container is angled upward and another downward to make it seem as though the building is reaching towards the sky and the ground.

The exterior of the containers was painted in bright yellow and black, which fits into the surrounding landscape very nicely. LOT:EK also used this project to test some innovative ways of assembling containers into buildings, such as cutting containers along unexpected angles, bending containers outside of their horizontal volume, and floating the containers in mid-air in defiance of their heavy mass.

The ground level of the school houses a public amphitheater, which also takes advantage of the existing sloping topography and is naturally divided into a lower seating areas, and a higher stage area. The second level features one large, open, space which can be used as a meeting/assembly room, or an exhibition space. There are also two artists-in-residence studios on this level.

The shorter sides of the containers had all been removed and replaced by windows, so as to maximize the natural daylight entering the building, as well as to allow for cross ventilation and offer great views of the surrounding countryside. The levels are connected via a stairway, which is housed inside one of the angled containers.

The art school was constructed as a partially prefabricated structure, since all the containers were cut and modified off site. These prefab modules were then transported to the building site on trucks, and, with the aid of a crane, connected to the main steel frame. After all the modules were in place, two teams worked on finishing it, one handling the interiors, and the other handling the exterior and landscaping. This saved a lot of time, and the building was completed in less than six months.

From www.jetsongreen.com